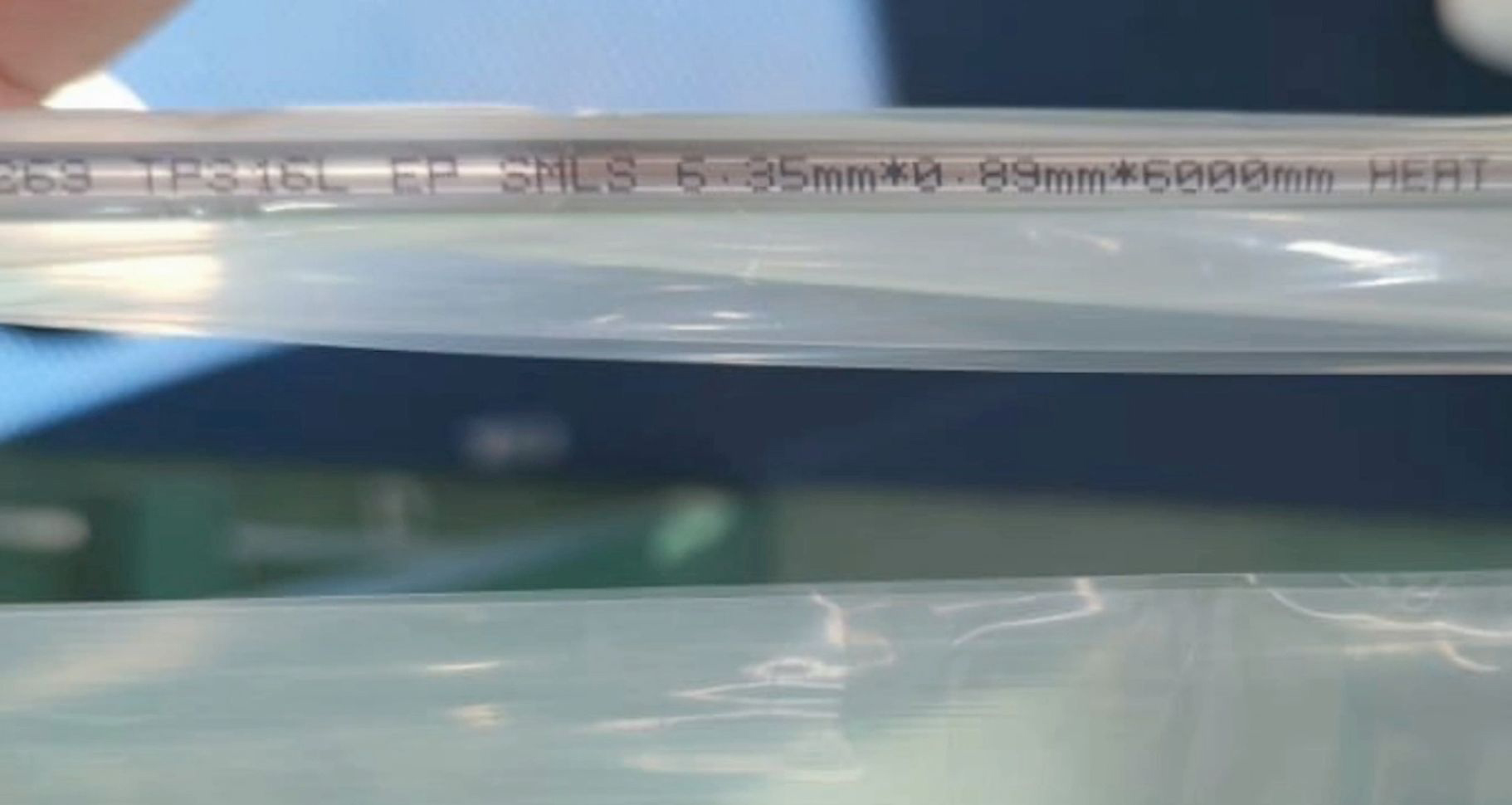

Electropolished (EP) Seamless Tube

Electropolishing yog dab tsi?

Electropolishingyog cov txheej txheem electrochemical tiav uas tshem tawm cov txheej nyias ntawm cov khoom siv hlau, feem ntau stainless hlau lossis cov hlau zoo sib xws. Cov txheej txheem tawm ntawm ci iab, du, ultra-ntshiab nto tiav.

Kuj hu uaelectrochemical polishing, anodic polishinglos yogelectrolytic polishing, electropolishing yog tshwj xeeb tshaj yog pab tau rau polishing thiab deburring qhov chaw uas tsis yooj yim los yog muaj complex geometry. Electropolishing txhim kho qhov chaw tiav los ntawm kev txo qhov roughness txog li 50%.

Electropolishing tuaj yeem xav taurov qab electroplating. Es tsis txhob ntxiv cov txheej nyias nyias ntawm cov hlau ions zoo, electropolishing siv hluav taws xob tam sim no los yaj txheej nyias ntawm cov hlau ions rau hauv cov tshuaj electrolyte.

Electropolishing ntawm stainless hlau yog feem ntau siv electropolishing. Electropolished stainless hlau muaj ib tug du, ci, ultra-ntxuav tag uas tiv thaiv corrosion. Txawm hais tias yuav luag txhua yam hlau yuav ua haujlwm, feem ntau cov hlau electropolished yog 300- thiab 400-series stainless hlau.

Kev ua tiav ntawm electroplating muaj cov qauv sib txawv rau kev siv sib txawv. Cov ntawv thov no xav tau qhov nruab nrab ntawm qhov kawg. Electropolishing yog ib txheej txheem los ntawm qhov tseeb roughness ntawm Electropolished Stainless hlau yeeb nkab yog txo. Qhov no ua rau cov kav dej muaj tseeb dua nyob rau hauv qhov ntev thiab Ep Pipe tuaj yeem ntsia tau nrog qhov tseeb hauv cov tshuab rhiab zoo li kev siv tshuaj siv tshuaj.

Peb muaj peb tus kheej polishing khoom thiab tsim electrolytic polishing raj uas ua tau raws li qhov yuav tsum tau ntawm ntau yam teb raws li kev taw qhia los ntawm Korean pab pawg neeg.

Peb EP Tube nyob rau hauv ISO14644-1 Chav Kawm 5 huv chav tsev, txhua lub raj yog purged nrog ultra siab purity (UHP) nitrogen thiab ces capped thiab ob hnab ntim. Daim ntawv pov thawj tsim nyog rau tubing cov qauv tsim, tshuaj muaj pes tsawg leeg, cov khoom siv traceability, thiab qhov siab tshaj plaws ntawm qhov roughness yog muab rau txhua yam khoom siv.

Specification

ASTM A213 / ASTM A269 Cov Lus Qhia

Roughness & Hardness

| Txuj kev tsim khoom | Sab hauv Roughness | Sab nraud Roughness | Hardness max |

| HRB | |||

| ASTM A 269 Cov khoom siv | Ra ≤ 0.25μm | Ra ≤ 0.50μm | 90 |

Relative Elemental Composition of Tube

Qhia 16939(1)

Txheej txheem

Txias dov / Cold drawing / Annealing / Electropolished

Khoom Qib

TP 316/316L

Ntim

Txhua lub raj tau raug purged los ntawm N2 roj, capped ntawm ob qho kawg, ntim rau hauv ob txheej txheej ntawm lub hnab huv huv thiab zaum kawg rau hauv rooj ntoo.

EP Tube Clean Room

Chav huv huv: ISO14644-1 Chav Kawm 5

Daim ntawv thov

Semi-conductor / Displays / Khoom noj khoom haus · kws tshuaj · bio ntau lawm cov khoom / Ultra ntshiab huv pipeline / Solar zog manufacturing khoom / Shipbuilding cav pipeline / Aerospace cav / Hydraulic thiab mechanical systems / Clean tsheb thauj mus los

Certificate Of Honour

ISO9001/2015 Txuj

ISO 45001/2018 Txuj

PED Certificate

TUV Hydrogen compatibility xeem daim ntawv pov thawj

FAQ

Stainless hlau 316L electropolished tube yog ib hom stainless hlau tubing uas tau txais kev kho tshwj xeeb nto hu ua electropolishing (EP). Nov yog cov ntsiab lus tseem ceeb:

- Khoom siv: Nws yog tsim los ntawm 316L stainless hlau, uas muaj cov ntsiab lus qis dua piv rau 304 stainless hlau. Qhov no ua rau nws muaj kev tiv thaiv corrosion ntau dua thiab tsim nyog rau cov ntawv thov uas muaj kev phom sij txaus ntshai.

- Deg tiav: Electropolishing cuam tshuam nrog submerging lub raj nyob rau hauv ib tug hluav taws xob them electrolyte tov da dej. Cov txheej txheem no dissolves imperfections ntawm los yog cia li hauv qab lub raj qhov chaw, uas ua rau ib tug du, uniform tiav. Lub puab nto roughness tau ntawv pov thawj kom muaj qhov siab tshaj plaws ntawm 10 micro-inch Ra.

- Daim ntawv thov:

- Kev lag luam kws tshuaj: Siv rau ultra-siab purity daim ntaub ntawv vim nws huv thiab corrosion kuj.

- Kev ua tshuaj lom neeg: Cov kab piv txwv rau kev kuaj H2S.

- Sanitary Piping Systems: Zoo tagnrho rau kev siv zaub mov thiab dej haus.

- Semiconductor Fabrication: Qhov twg zoo smoothing ntawm lub raj yog qhov tseem ceeb.

- Daim ntawv pov thawj: Kev tswj xyuas tshwj xeeb rau electropolished tubing yog ASTM A269, A632, thiab A1016. Txhua lub raj yog purged nrog ultra-high purity nitrogen, capped, thiab ob-bagged nyob rau hauv ISO Class 4 huv chav tsev.

Electropolished tubing muaj ntau yam zoo:

- Corrosion Resistance: Cov txheej txheem electropolishing tshem tawm cov imperfections saum npoo, txhim kho cov khoom tiv thaiv corrosion thiab pitting.

- Smooth Surface Finish: Qhov ua tiav daim iav zoo li qhov kawg txo kev sib txhuam, ua kom yooj yim rau kev ntxuav thiab tswj. Qhov no yog qhov tseem ceeb rau kev siv tshuaj, kev ua zaub mov, thiab kev lag luam semiconductor.

- Txhim kho huv huv: Electropolished tubes muaj tsawg crevices thiab micro-roughness, txo qhov kev pheej hmoo ntawm cov kab mob loj hlob. Lawv yog cov zoo tagnrho rau kev siv huv huv.

- Txo Cov Kab Mob Tsis Txaus Ntsig: Lub ntsej muag du tsis pub cov khoom thiab cov kab mob sib kis los ntawm kev sib txuas, ua kom cov khoom purity.

- Enhanced Aesthetics: Lub polished tsos yog visually txaus siab thiab haum rau high-end daim ntaub ntawv.

Electropolished tubing feem ntau yog siv nyob rau hauv qhov chaw tseem ceeb qhov chaw huv si, corrosion resistance, thiab du nto yog qhov tseem ceeb.

| Tsis muaj. | Loj | |

| OD (mm) | Thx (mm) | |

| 1/4 " | 6.35 Nws | 0.89 ib |

| 3/8 " | 9.53 ib | 0.89 ib |

| 1/2 " | 12.70 Nws | 1.24 |

| 3/4 " | 19.05 Nws | 1.65 ib |

| 3/4 " | 19.05 Nws | 2.11 |

| 1 ″ | 25.40 Nws | 1.65 ib |

| 1 ″ | 25.40 Nws | 2.11 |

| 1-1/4 " | 31.75 Nws | 1.65 ib |

| 1-1/2 " | 38.10 Nws | 1.65 ib |

| 2 ″ | 50.80 Nws | 1.65 ib |

| 10 A | 17.30 Nws | 1.20 |

| 15 A | 21.70 Nws | 1.65 ib |

| 20 A | 27.20 Nws | 1.65 ib |

| 25 A | 34.00 Nws | 1.65 ib |

| 32 A | 42.70 Nws | 1.65 ib |

| 40 A | 48.60 Nws | 1.65 ib |